Slurry Pump vs. Mud Pump: Buyer's Guide and Market Trend Analysis

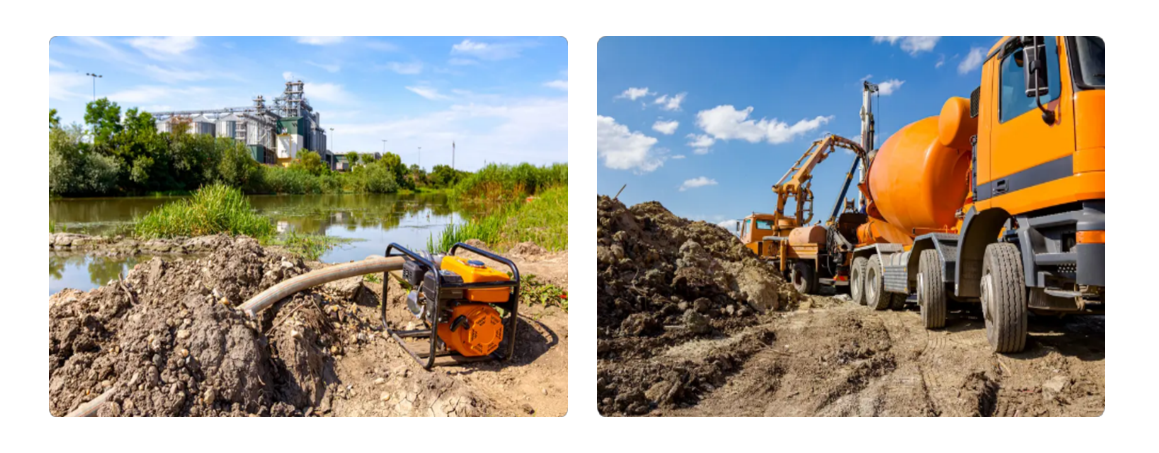

In harsh working conditions

Highly efficient pumps such as mud pumps and slurry pumps are becoming core tools in the mining, metallurgical, and environmental protection industries.

With the growing demand for conveying slurries containing solid particles in these industries, slurry pumps and mud pumps, as key equipment, are rapidly expanding their use. While both are common fluid conveying devices, they differ in their application scenarios and operating principles.

01 Key Differences Between Slurry Pump and Mud Pum

Despite their similar names, mud pumps and slurry pumps differ significantly in their design and application.

① Medium: A slurry pump is designed specifically for conveying slurries containing larger particles and higher hardness, and is typically used to process materials such as ore and coal slag. Mud pumps are primarily used to convey slurries containing finer particles and higher viscosity, such as drilling mud and muddy water in underground engineering projects.

② Structure and Materials: To withstand high wear, slurry pump flow components are typically constructed of high-strength, wear-resistant materials such as high-chromium alloys and wear-resistant ceramics, effectively withstanding the impact of hard particles. Mud pumps, on the other hand, primarily handle silt from river desilting and slurry in construction shields. Therefore, they prioritize sealing and leak-proofing, and their material selection prioritizes corrosion resistance.

③ Working Principle: A slurry pump uses a motor to drive the impeller, increasing the kinetic energy of the slurry. A mud pump, on the other hand, uses piston movement to cause changes in the volume of a sealed chamber, completing the water intake and discharge process. ④ Application Areas: If the main problem during the operation is the high hardness and concentration of solid particles, such as mining slurry transportation and metallurgical waste slag treatment, choose Slurry Pump. If the core problem is high viscosity of the medium and easy precipitation and clogging, such as river dredging and sewage treatment plant sludge transportation, choose Mud Pump.

02 Global Market Structure and Regional Demand

Global market demand is diverse, and product demand varies across regions due to policy factors.

According to statistics, Slurry Pumps are in strong demand in countries like Russia, Kazakhstan, and Mexico; Mud Pumps' primary markets are Vietnam, India, and Turkey.

03 Expanded Application Areas and Applicable Environments

Slurry and mud pumps have been used in numerous industrial sectors.

In the mining industry, they are used to transport ore slurry, coal slurry, and tailings; in the metallurgical industry, they are used to handle slag and oxides; and in the power industry, they are primarily used to transport coal ash.

The environmental protection industry has become a key application area for slurry pumps, with sewage treatment plants using them to handle sediment and sludge.

04 Future Industry Development Trends

Material advancements and technological innovations offer greater potential for improving the performance of slurry and mud pumps.

As global buyers increasingly prioritize environmental protection, energy-saving and environmentally friendly slurry pumps will become mainstream. Furthermore, advances in materials science will promote the use of new wear-resistant materials, significantly extending pump life.

Pump technology development will exhibit a diversified trend in the future. As global demand for technological infrastructure construction and resource extraction continues to expand, high-efficiency products will become the preferred choice for buyers. True to our commitment to "Reliability, Never Stopping," each of our meticulously crafted slurry and mud pumps is designed to provide global customers with exceptional durability and operational value, ensuring stable operation under challenging conditions.